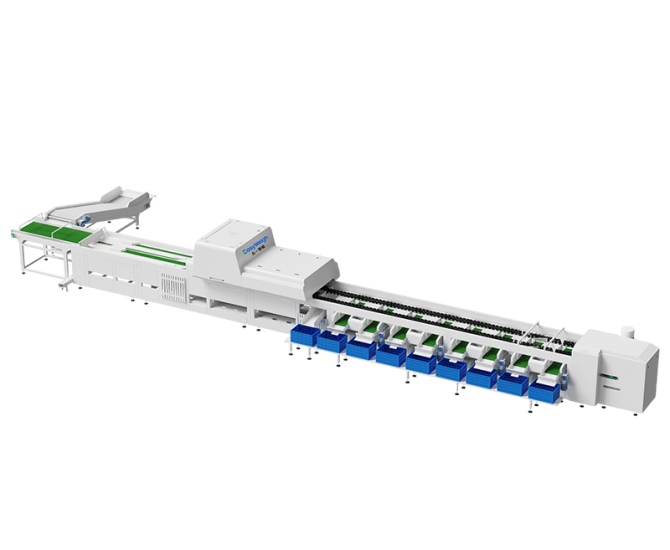

Efficient food processing is essential for modern production lines, and WEIGHT SORTING provides equipment that addresses this need. By incorporating a sorter machine into production workflows, manufacturers can reduce manual labor, minimize errors, and maintain consistent quality across batches. These machines are designed to handle a variety of products, from fruits and vegetables to packaged goods, providing reliable performance that adapts to different operational requirements.

Precision Handling for Diverse Products

The sorter machine from WEIGHT SORTING uses precise weighing and detection technology to separate products based on size, weight, and quality characteristics. This ensures that only items meeting predefined standards proceed through the production line. By automating these processes, the system reduces the likelihood of human error while improving throughput. The flexibility of these machines allows them to handle both delicate items and heavier products without compromising accuracy.

Integrating Data and Workflow Efficiency

Modern sorter machines offer features that integrate data collection and real-time monitoring. They allow manufacturers to track product flow, identify inconsistencies, and make adjustments quickly. With these capabilities, production lines can maintain higher efficiency and reduce downtime. The AI-enabled optical sorting technology, often paired with WEIGHT SORTING systems, analyzes product characteristics continuously, refining sorting parameters to improve speed and precision over time.

Improving Productivity and Consistency

By using a sorter machine, food processing companies can achieve higher consistency in their output while maintaining safety and quality standards. These machines help streamline operations, minimize waste, and support compliance with food industry regulations. The automation also allows employees to focus on other critical tasks, enhancing overall productivity without sacrificing control over the sorting process.