Selecting the right air dryer desiccant type is crucial for ensuring high-quality compressed air, protecting equipment, and maintaining operational efficiency. With multiple desiccant technologies available, understanding their differences can help facilities make an informed choice that fits both application requirements and budget.

Types of Desiccant Air Dryers

1. Heatless Desiccant Air Dryers

How it Works: Uses a portion of dry compressed air to regenerate the desiccant without external heat.

Advantages:

Simple design, low maintenance

Achieves ultra-low dew points (-40°C or lower)

Reliable for sensitive operations

Disadvantages:

Consumes purge air (typically 15% of compressed air flow)

Slightly higher operating cost due to air consumption

2. Heated (Blower or Externally Heated) Desiccant Air Dryers

How it Works: Uses an external heat source to regenerate desiccant, reducing purge air consumption.

Advantages:

More energy-efficient compared to heatless dryers

Reduced compressed air loss during regeneration

Suitable for large-scale industrial operations

Disadvantages:

More complex design, requires heating equipment

Higher initial investment

3. Refrigerated + Desiccant Hybrid Dryers

How it Works: Combines refrigerated drying for bulk moisture removal with desiccant drying for ultra-low dew points.

Advantages:

Highly efficient, especially in humid conditions

Provides stable, extremely dry air

Ideal for critical manufacturing and instrumentation

Disadvantages:

Higher upfront cost

More complex maintenance

Factors to Consider When Choosing a Desiccant Type

Required Dew Point: Critical for industries like pharmaceuticals, electronics, and food processing.

Air Flow and Pressure: Large facilities may benefit from heated or hybrid dryers to optimize efficiency.

Operating Environment: Cold or fluctuating temperatures favor desiccant systems over refrigerated dryers.

Maintenance and Operating Costs: Simpler systems like heatless dryers are easier to maintain, but may consume more compressed air.

Conclusion

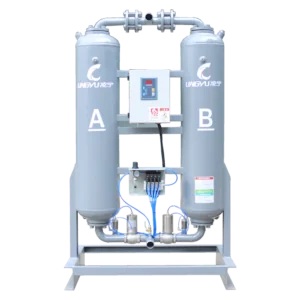

Choosing the correct air dryer desiccant type ensures reliable performance, protects sensitive equipment, and supports consistent production quality. Facilities should weigh factors such as dew point requirements, air consumption, and operating environment when making their selection. Lingyu compressed air system‘s industrial desiccant air dryers offer a variety of desiccant solutions, designed to provide reliable, cost-effective, and high-performance compressed air treatment for diverse industrial applications.