In industries handling mixed-SKU inventory, fragile components, or irregularly shaped parts—such as e-commerce fulfillment, medical device assembly, or food processing—adaptive grippers have become essential for minimizing manual intervention and maximizing uptime. DH-Robotics specializes in them that combine sensor-driven feedback, compliant materials, and modular finger designs to handle diverse objects without tooling changes. This article explores how their solutions enable robots to match human-like dexterity, reducing production bottlenecks and waste.

Red Dot Award-Winning AG Series: Precision Meets Ergonomics

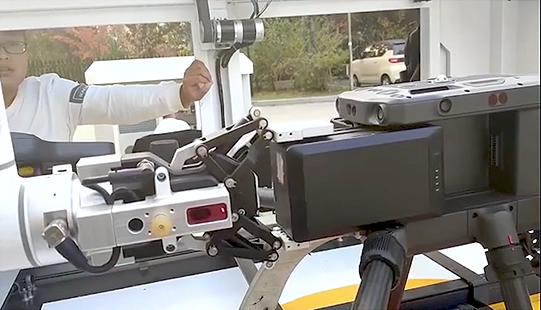

DH-Robotics’ flagship AG series adaptive grippers earned the Red Dot Design Award for their blend of technical innovation and user-centric engineering. Featuring a lightweight carbon fiber body and intuitive quick-change finger system, these grippers reduce robot payload demands while allowing operators to swap end-effectors in seconds.

Multi-Sensor Fusion for Real-Time Adaptation

To handle high-speed applications, DH-Robotics integrates force-torque sensors, proximity detectors, and tactile arrays into their adaptive grippers, enabling real-time adjustments during pick-and-place cycles. In a semiconductor testing line, their AG-Pro model detected wafer misalignment mid-motion and corrected its grip trajectory, preventing costly breakage. The grippers’ Ethernet/IP connectivity also allows seamless integration with PLCs, while built-in diagnostics alert operators to wear or calibration needs via HMI dashboards.

Self-Adjusting Grippers: Flex Meets Precision

DH-Robotics’ adaptive grippers set a new standard for flexible automation by merging award-winning design, self-adjusting compliance, and intelligent sensing. As industries face increasing pressure to handle diverse product lines efficiently, their solutions empower robots to tackle unpredictable tasks with minimal human oversight. Whether sorting recyclables or assembling microelectronics, they deliver the dexterity and reliability needed to optimize modern production workflows.