Junyi offers a comprehensive range of lean pipes and their components that significantly contribute to reducing production costs. These innovative solutions are designed for reusability, minimizing waste and promoting sustainable manufacturing practices. The ability to easily modify these coated pipes allows manufacturers to make quick structural adjustments and functional expansions, ultimately leading to increased efficiency on the production floor.

Reduce Production Costs

Lean pipes from Junyi are a cost-effective solution for manufacturers looking to optimize operations. By using reusable coated pipe, companies can significantly lower production costs. The ease of modification inherent in lean pipe systems means that businesses can quickly adapt their setups to meet changing demands without incurring significant additional costs. This flexibility allows for a more responsive manufacturing process, enabling companies to stay competitive in a fast-paced market.

Enhance Product and Workplace Safety

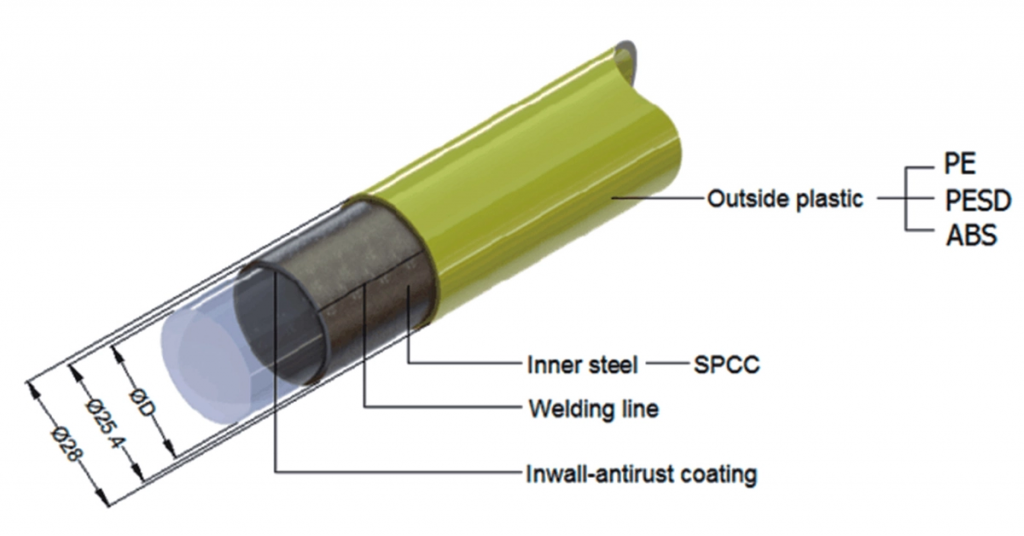

Another crucial advantage of lean pipes is their contribution to enhanced product and workplace safety. The outer plastic coating of Junyi’s plastic coated pipe protects delicate components from damage, ensuring that products remain intact during handling and transportation. Additionally, this protective layer helps reduce the risk of workplace injuries, creating a safer environment for employees. By prioritizing safety, Junyi helps businesses foster a culture of well-being and efficiency.

Conclusion

In conclusion, Junyi’s coated pipes provide significant benefits for modern manufacturing. The reusability of these plastic coated pipes not only reduces production costs but also minimizes waste, aligning with sustainable practices. Furthermore, the safety features of Junyi’s coated pipe contributes to a safer workplace, making them an essential choice for businesses aiming to enhance both efficiency and safety in their operations. As a coated pipe factory, Junyi is committed to delivering high-quality solutions.